Tilting Pad Journal and Thrust Bearings are responsible for enhancing the maximum operational speed of turbomachinery by eliminating instabilities such as oil whirl. Due to the strong convergence of the lubricant film by each loaded pad, the shaft remains properly centered within the bearing housing. As a result, the unsteady forces are significantly reduced or entirely eliminated, and the bearings no longer act as a potential source of dynamic instability in the equipment.

With improved operational efficiency and reliability, operators benefit from extended equipment uptime, reduced frequency of scheduled maintenance, and lower servicing and repair costs. These advantages have led tilting pad bearings to become the standard choice for high-speed turbomachinery applications.

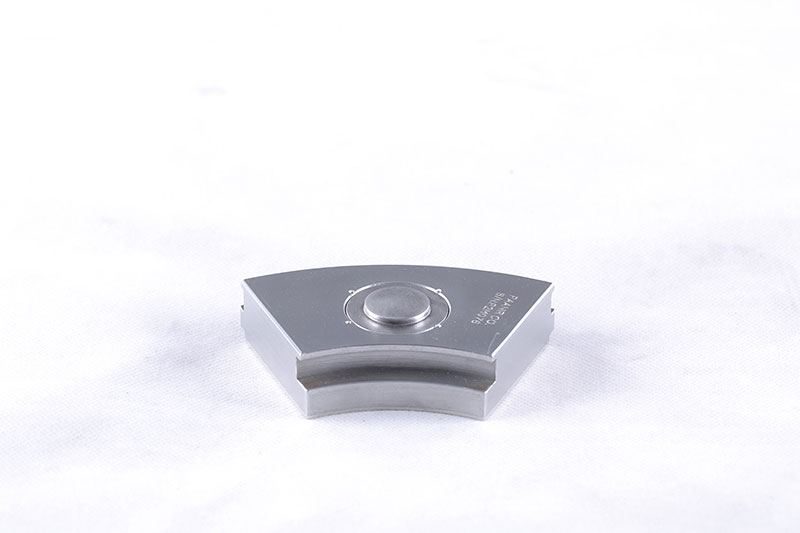

In tilting pad thrust bearings, a set of auxiliary components known as leveling plates is also employed to prevent axial load from being concentrated on a single point of the thrust surface. This design feature helps protect the bearing from damage and ensures more reliable equipment performance.